Total Quality Management

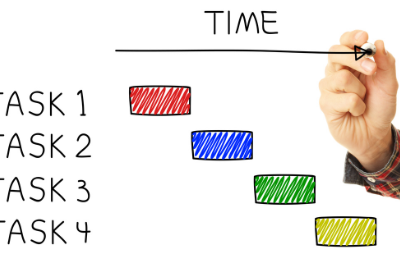

COURSE DESCRIPTION Kanban (Japanese: 看板, meaning signboard or billboard) is a lean method to manage and improve human-system work. This approach aims to manage work by balancing demands with available capacity and improving the handling of system-level bottlenecks. Kanban is useful for you if you work …

Overview

COURSE DESCRIPTION

Kanban (Japanese: 看板, meaning signboard or billboard) is a lean method to manage and improve human-system work.

This approach aims to manage work by balancing demands with available capacity and improving the handling of system-level bottlenecks.

Kanban is useful for you if you work directly with service and operation. For example, rmg, food, pharmaceuticals, other manufacturing, banking, software, supply chain, and other services.

Kanban

One of the better-known Lean Tools is Kanban. Kanban means ensure signal (card), which is precisely the idea: using a simple tool that everyone understands to ensure that a signal is transmitted. In this case, the call to order raw materials/parts. The kanban indicates that the amount in question needs to be ordered. The card usually also contains the quantity, the order number, the supplier, a bar code, etc.

The Kanban tool is used in everyday practice in many warehouses. On the shelf, a card appears when an article is picked up when a shortage is imminent. A card In everyday life, we see the same principle being used with cigarette rolling papers, with a colored paper indicating there are only ten papers left, signaling the user to go out and buy new cigarette papers.

In the banking world, the same principle used to be applied to checkbooks: 10 cards before the end, there would be a form that people could use to order a new checkbook. Whenever a cash roll is about to run out in supermarkets, it is indicated with a purple bar on the paper.

Curriculum

Instructor

Requirements

- Graduation in any discipline

Target audiences

- Operation Manager

- Supply Chain manager

- Quality Control Manager